Goat Milking Equipment: A Comprehensive Guide

Milking goats is an essential aspect of dairy farming, and efficient milking equipment plays a crucial role in maintaining the health and productivity of the herd. Modern goat farmers rely on various types of milking equipment to ensure a hygienic, stress-free, and efficient milking process. In this comprehensive guide, we will explore the different types of goat milking equipment, their functions, and the factors to consider when selecting the right equipment for your farm.

1. Milking Machine:

Milking machines are the heart of any commercial goat dairy operation. These devices automate the milking process and help increase milking efficiency while reducing labor requirements. A milking machine consists of a vacuum pump, pulsation system, milk claw, teat cups, milk lines, and a milk receiver jar.

The vacuum pump creates the necessary suction to draw milk from the goat’s udder into the milk claw through the teat cups. The pulsation system mimics the natural sucking rhythm of a kid, stimulating milk letdown and preventing damage to the goat’s teats.

2. Milk Claw:

The milk claw is a component of the milking machine that collects milk from multiple teats simultaneously. It usually has 4 to 8 ports, allowing the milking of several goats at once. Milk claws are designed to be easily detachable, allowing for quick and efficient switching between goats during the milking process.

3. Teat Cups:

Teat cups are attached to the milk claw and directly connect to the goat’s teats. They come in various sizes to fit different teat shapes and sizes. Properly fitted teat cups are essential to ensure effective and comfortable milking, reducing the risk of injury to the goat’s udder.

4. Milk Lines:

Milk lines are flexible tubes that connect the teat cups to the milk claw and transport the milk from the udder to the milk receiver jar. These lines are typically made of food-grade silicone or rubber, ensuring milk quality and hygiene.

5. Milk Receiver Jar:

The milk receiver jar is where the milk collected from the goat is temporarily stored. It serves as a buffer between the milking machine and the bulk milk tank. This jar is equipped with a float valve that automatically shuts off the vacuum and milk flow once it reaches a certain level, preventing milk overflow.

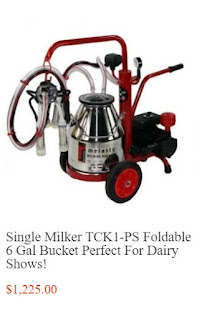

6. Bucket Milking System:

In smaller-scale or traditional goat farming setups, a bucket milking system is often used. This system comprises a milking bucket with teat cups attached directly to the lid. The milker manually operates a vacuum pump, creating suction to draw milk from the goat’s udder into the bucket. This method is less automated than milking machines but can still be effective for small herds.

7. Pre-milking Preparation:

Proper pre-milking preparation is crucial for maintaining milk quality and goat health. Before milking, goats should have their udders cleaned thoroughly to remove dirt and debris. Pre-milking teat dipping is often done to reduce the risk of mastitis and to maintain teat health. This involves applying an antiseptic teat dip to each teat, which kills bacteria and prevents infection.

8. Post-milking Care:

After milking, it’s essential to care for the goat’s udder and teats properly. Post-milking teat dipping is performed to provide a protective barrier against bacteria and promote teat health. The milking equipment should be cleaned and sanitized after each use to prevent contamination of the milk.

Factors to Consider When Choosing Goat Milking Equipment:

Selecting the right milking equipment for your goat farm depends on several factors, including:

1. Herd Size:

The number of goats you have will determine whether a milking machine or bucket milking system is more suitable. For larger herds, milking machines are more efficient, while smaller herds may find bucket milking systems sufficient.

2. Automation:

Consider the level of automation you desire. Milking machines offer more automation and require less manual labor, while bucket milking systems are more hands-on.

3. Budget:

Milking machines can be a significant investment, so consider your budget and long-term profitability.

4. Maintenance and Cleaning:

Evaluate the maintenance requirements of the equipment and how easy it is to clean and sanitize.

5. Milking Speed:

Milking machines can be faster than manual milking, which is advantageous for larger herds.

6. Milk Quality:

High-quality milking equipment and proper milking procedures are crucial for maintaining milk quality and preventing contamination.

Conclusion:

Efficient and well-maintained milking equipment is vital for successful goat dairy farming. Whether you opt for a milking machine or a bucket milking system, ensuring proper milking practices and hygiene will promote the health and productivity of your goat herd, resulting in high-quality milk and a thriving dairy operation. Remember to consider factors such as herd size, automation level, and budget when selecting the right milking equipment for your farm. With the right equipment and care, your goats will produce top-quality milk, making your dairy venture a success.

Comments

Post a Comment